Inverters reduce electric motor energy consumption while also offering better control. Processes like aeration, chemical infeed and sewage treatment can be more precisely controlled using inverters on various pumps and motors.

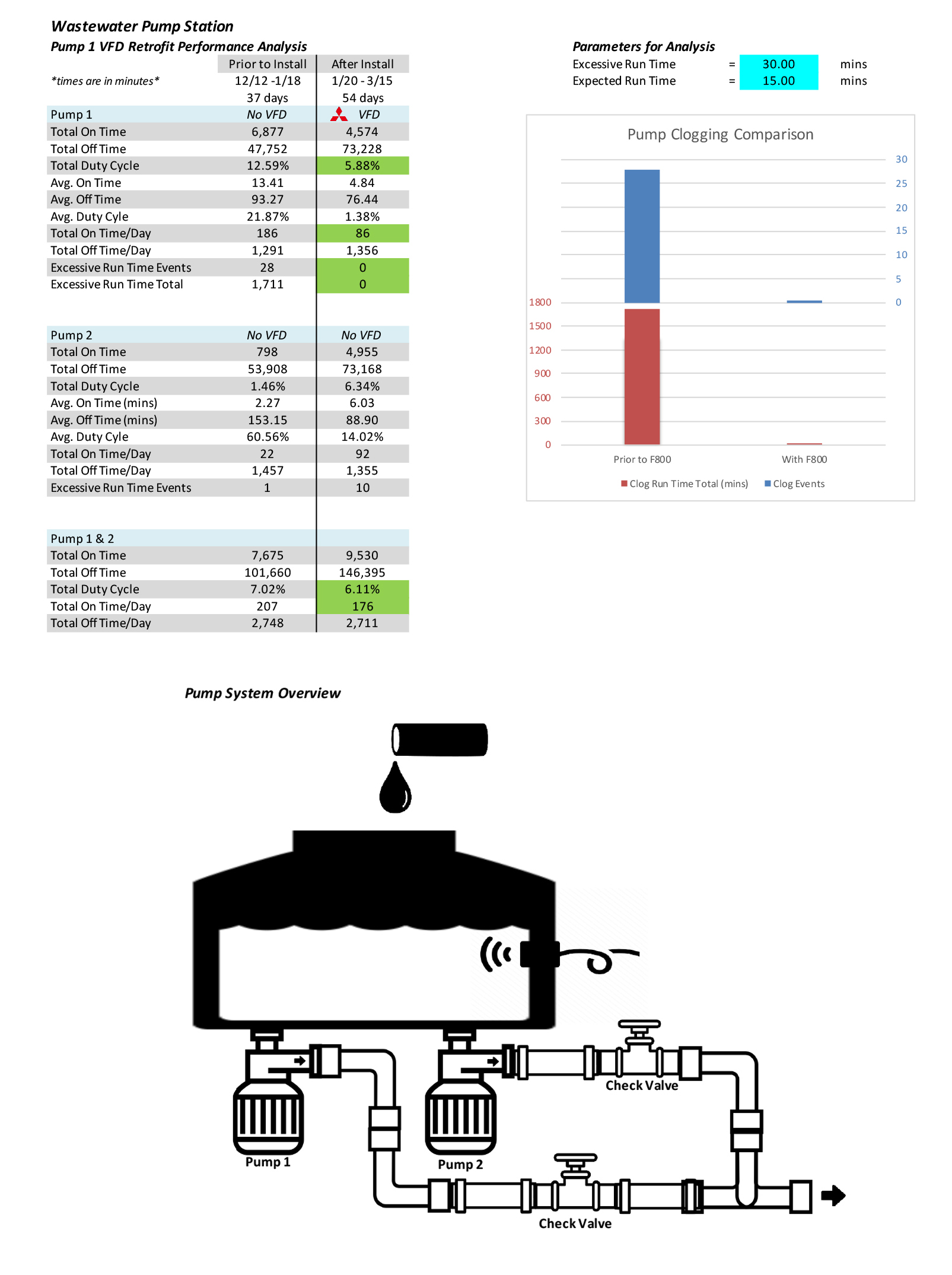

De-Ragging/Pump Cleaning feature detects an excess increase in pressure and triggers a self-clearing sequence that will consist of increasing power and/or cycling the pump back and forward to dislodge the blockage.

Inverter controlled pumps are used to match supply to demand throughout the distribution network. They provide more water at peak times and trim it back as demand drops off. Reducing pressure in the distribution network also plays an important role in reducing losses due to leakage.

- Reduced energy consumption

- Up to 50% energy savings in aeration blowers

- Reduced vibration and “water hammer” effect

- Cleaning/De-ragging function (Pump cleaning)

- Better control of blower fans and pumps

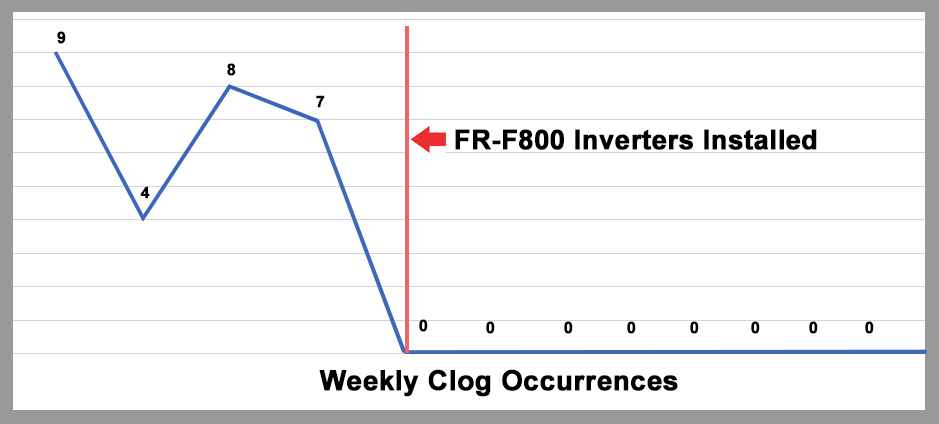

View the complete data illustrating the impact of installing FR-F800 inverters

“Rags, wet wipes and towels caused on average 2 clogs per week resulting in 4 hours of tedious service calls to clean out clogs via pump access plates. Mitsubishi’s “De-clogging” feature has eliminated these issues completely over the past 3 months.”

Matt Powers

Murfreesboro City Water

Reduce Risk of Downtime with a VFD that Eliminates Clogs

Variable frequency drives have long been used in wastewater treatment plants because they offer a range of efficiency and cost-saving benefits, but today’s VFDs can do even more by tackling common industry issues.See how VFDs are leveraging advanced technology to keep treatment plant pumps clear of clogs and running at peak performance. READ THE ARTICLE

Anti-Clogging with VFDs: What You Need to Know To Avoid Pump Lockup - On-Demand Webcast

Variable frequency drives have long been used to optimize control in water/wastewater applications, but VFDs tailored to take on specific challenges in this industry are relatively new. Learn how a VFD can allow you to reliably avoid pump clogging and lockup by executing a forward/reverse timing sequence and removing clogging material from the pump’s impellers, along with other features created to combat common challenges in these applications.In this webcast, Ruben Ortiz, product manager for large capacity drives at Mitsubishi Electric, discusses:

- Why pump clogging happens and how the problem is growing

- The technology behind the anti-clog feature

- How VFDs increase efficiency and bring down cost

Sewer systems across the country are warning customers not to flush those so called ‘flushable’ wipes.’ The products have been growing in popularity since the toilet paper shortage spurred by the pandemic. But unlike toilet paper which disintegrates in water, the wipes don’t break down. READ THE ARTICLE