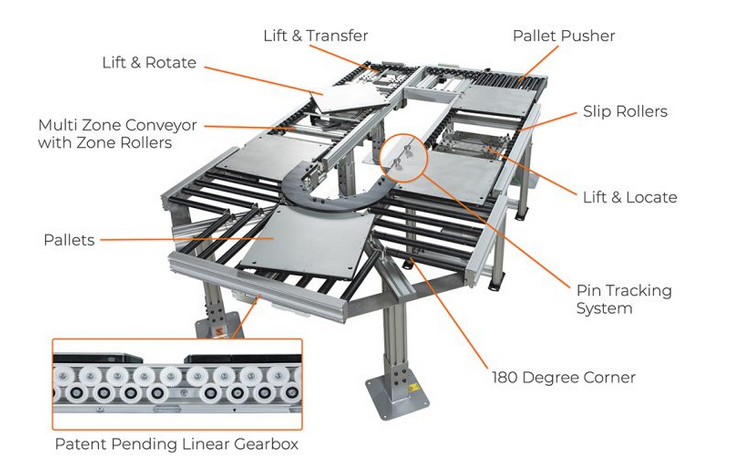

Dorner’s new precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for medium & heavy load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 approved for cleanrooms.

The ERT 250 is built for cleanroom applications such as medical product and device manufacturing, assembly, and packaging, as well as medium-large heavy load assembly automation applications.

What Makes the ERT so different?

The simple, yet robust, design provides long-term durability and ease of single point roller maintenance. The force to move product has almost no friction which means less debris, dust, and chances for contamination.

Additionally, slip roller technology reduces the force by almost 75%, and the force to accumulate product with driven roller is less than that of belted conveyors. The rollers are driven by a patent-pending, energy efficient linear gearbox that gives customers added flexibility with motor positioning and zoning.

- Widths 120 mm to 960 mm wide

- 38 mm diameter rollers on 50 mm centers

- Loads up to 250 pounds per pallet or tray

- Loads up to 15 pounds per roller

- 150 mm minimum long tray

- Speeds up to 30 m (100 feet) per minute

- Aluminum frame with two T-slots

- Energy efficient brushless DC gearmotors and controllers; motor controllers use Ethernet IP for easy communication

- Reversible

More ERT 250 Edge Roller information